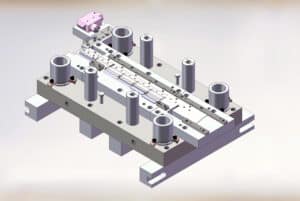

R&M offers design and engineering assistance to help our customers create the best parts and mechanical assemblies possible. We work with customers with full engineering departments, customers without any engineers on staff, and everyone in-between. Here’s an in-depth look at

our CAD services.

WE’RE SOFTWARE COMPATIBLE

The software we use internally is tailored for tool and die design. It has many additional features that more general-use software lacks. So, we can take your design and optimize it for qualities specific to tool and die design.

Plus, our key creator gives us the capabilities to open designs created in a lot of different formats. I’d say we’re able to open 95 percent of what we come across, without issue.

WE ACCEPT ROUGH CONCEPTS

Customers can come to us with all different situations where they need a prototype. Here are three examples of common starting points.

“BAR NAPKIN” DRAWINGS

If your prototype idea seems stuck in two dimensions, we can help. An original design can be sketched – or scribbled – on a scrap of paper. We can generate a 3D model with our system to match your design and go from there.

REVERSE ENGINEERING

Sometimes, our customers bring us a physical part that they need a tool built for. From the original component, we’re able to reverse engineer, draw up a 3D model, and build a prototype.

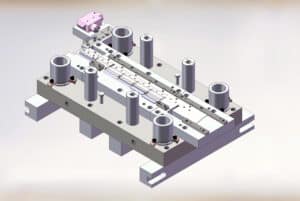

MAKING IT MORE ECONOMICAL

With our CAD services, we can work out ways to make a component less expensive without making it cheaper. If there is a more economical way to make a part, we can figure it out. Then, we can create a prototype and run it by the customer.

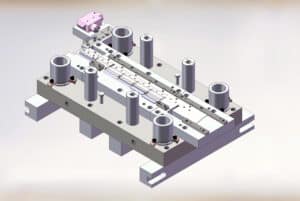

WE BUILD TOOLS AS IF WE’RE GOING TO RUN THEM

Another great thing about having our own in-house CAD services is that we have design and engineering expertise specific to metal fabrication. Many of our customers have their own engineering departments, but their area of expertise isn’t in

metal fabrication.

If we receive a design from a customer that isn’t meeting the guidelines for good stamping processes, we’re going to let them know. Not only that, we’re able to make suggestions and tweak the design on our end and just send it back to the customer for approval. This way, the design doesn’t get held up in a back and forth.

You’re likely to run across tool and die fabricators that’ll just take your specs and make what you’ve requested, even if it’s a tool that’s going to fail. But that’s not us. We want our customers to have tools that perform to their very best, which is why we build tools as if we’re going to run them.

The software we use internally is tailored for tool and die design. It has many additional features that more general-use software lacks. So, we can take your design and optimize it for qualities specific to tool and die design.

Plus, our key creator gives us the capabilities to open designs created in a lot of different formats. I’d say we’re able to open 95 percent of what we come across, without issue.

The software we use internally is tailored for tool and die design. It has many additional features that more general-use software lacks. So, we can take your design and optimize it for qualities specific to tool and die design.

Plus, our key creator gives us the capabilities to open designs created in a lot of different formats. I’d say we’re able to open 95 percent of what we come across, without issue.

The software we use internally is tailored for tool and die design. It has many additional features that more general-use software lacks. So, we can take your design and optimize it for qualities specific to tool and die design.

Plus, our key creator gives us the capabilities to open designs created in a lot of different formats. I’d say we’re able to open 95 percent of what we come across, without issue.

The software we use internally is tailored for tool and die design. It has many additional features that more general-use software lacks. So, we can take your design and optimize it for qualities specific to tool and die design.

Plus, our key creator gives us the capabilities to open designs created in a lot of different formats. I’d say we’re able to open 95 percent of what we come across, without issue.